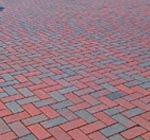

Shot Blasted Paver Blocks

The product is a newly developed technology, which provides a weathered or natural stone finish to the paver blocks; exhibits remarkable aesthetical finish. The raw materials include normal cement concrete, crushed granite and marble stones etc.

A series of production and post-production activities are involved in achieving the desired texture and finish. Products are a bit expensive compared to the conventional paver blocks because of the complexity involved in its production. The products are mainly served in the landscaped areas of premium apartments, shopping malls, hotels and other commercial buildings.

High Density Interlock Paver Blocks

This product is manufactured from high grade cement concrete, involving a series of manufacturing processes. The Products are further classified based on their thickness, shape and load bearing capacity. They can be provided in concrete grades of M-50, M-40, M-30. The products are mainly served for Industrial Stack Yards, Heavy Traffic Roads, Vehicle Parking Areas, Shipping Terminals, Petroleum retail Outlets, Road over Bridges etc.

The products are manufactured in some limited variety patterns and shades which are approved under all Indian and International Standards. All the raw materials used for manufacturing and the process of manufacturing strictly meets the IS Standard (IS: 15658: 2006).

Polymer Molded Reflective

Type Designer Interlock

Paver Blocks

The product mainly meets the domestic requirements or commercial establishments. The product exhibits high aesthetical finish since they are individually molded from polymer moulds.

The raw materials include normal concrete, chemical admixtures and other pigments to provide the desired colour and finish. The process also includes a typical state of art polishing procedure to provide a reflective coating above the finished surface. The main areas served are Small drive ways, Walkways, landscaped path ways, courtyards of commercial buildings, Internal roads of Apartment complexes, Domestic Car park areas etc.

Construction and Building Materials

The other products manufactured are Solid / hollow blocks with high dimensional accuracy and competent strength in various sizes according to the requirement. We also manufacture Green building products like Fly ash bricks which can be manufactured in various size and pattern depending on the requirement.

Moreover to that we manufacture High density Kerbstones which are used to retain the end surfaces of roads or any paved areas. Precast retaining wall Blocks, precast Drains and Cover slabs etc are our other products which have great role in the Infrastructure development. These can be provided in a limited variety of colour and pattern which meets the approved standards and design.

Manufacturing Plants

1. 15L Columbia Plant – The company holds 600 lakhs worth fully automated manufacturing plant at Shornur, Kerala with a production capacity to cater around 10000Sq. M area per month. The plant comprises of one 15 L Columbia machines imported from USA through Columbia Pakona (Mumbai). The raw material handling, mixing and conveying is carried out from an automatic Mixing & Batching plant of MACONS with a batching capacity of around 96 Cu. M concrete per shift. All the processes are undertaken with utmost quality and care.

2. Designer paver Plant -

A fully equipped designer paver plant exclusively for production of reflective type paver blocks has been set up to meet the varying market requirements. Superior quality in the products and a capacity to cater to around 5000sq.m. area per month in limited variety patterns are the highlight in the sector.

3. Shot Blasting Machine -

A shot blasting machine which is fully automated and is capable of delivering 300 Sq.m per shift to cater to the premium products clientele in the region.